Ball valves handle a range of inlet and outlet pipe diameters and must be sized according to several considerations:

Match the flow coefficient (Cv) value range of the ball valve to actual system flow volumes. Undersized valves restrict flow, while oversized ones see reduced rangeability.

Pressure ratings correlate with valve body wall thickness and materials. Select ratings suitable for service pressures plus a safety margin.

Inlet/outlet pipe connections must properly suit system piping. This includes matching inside diameters for minimal flow losses.

Ensure pressure rating holds up under fluid temperatures that propagate through the valve body in service.

Adhere to applicable codes governing flow calculations and piping classifications to arrive at accurate valve sizing.

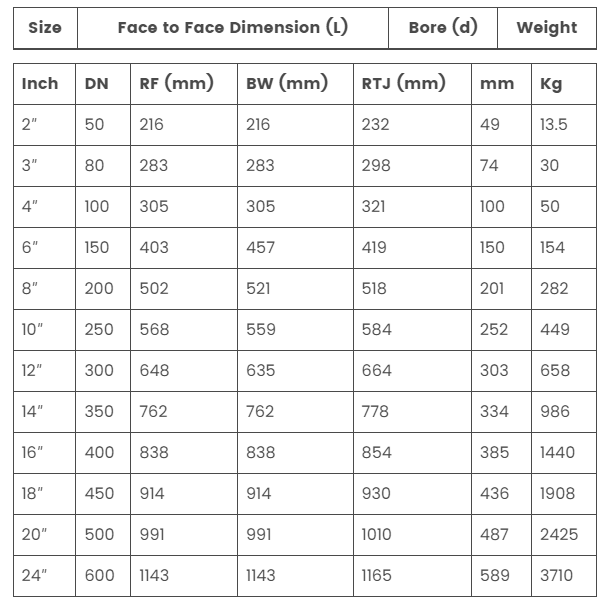

For standardized steel ball valves, common dimensions help technicians verify proper fits and performance capabilities. The below table outlines key measurements for Class 300 flanged ball valve dimensions – ranging from 2 inches to 24 inches:

Note: The weights for sizes 2-4″ correspond to floating ball valves with cast steel bodies. For sizes 6″ and larger, the weights are for trunnion-mounted ball valves with forged steel bodies.

Ball valve dimensions impact leak prevention, flow efficiency, and system safety. Always:

✔ Confirm valve size (NPS/DN) and pressure class.

✔ Compare standards (ANSI vs. DIN vs. JIS).

✔ Check actuator compatibility (ISO 5211).