Tel : +86-18059296519

Whatsapp : +8618059296519

Email : [email protected]

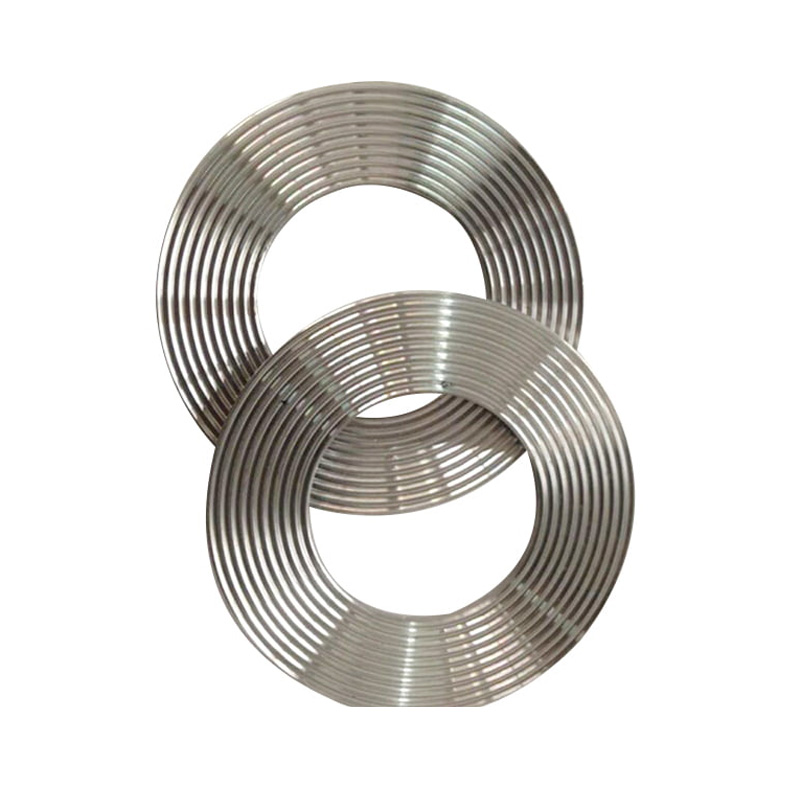

A Spiral Wound Gasket is the most common metallic gasket used in industrial plants. A properly selected and installed spiral wound gasket can withstand high temperatures and pressures, preventing leaks throughout their intended lifespan.

Metal Jacketed Gasket

A spiral wound gasket consists of three elements:

Metal Jacketed Gasket is based on 0.2-0.6 mm thick soft metallic stripe which acts as the shell material, filled with non-nature fibre like graphite, asbestos or ceramics. It often needs some certain shape rods when used in heat exchanger. We can produce square, oval and other sort of shapes metal jacketed gasket. According to their shell material and filler material, the maximum operating pressure and temperature are normally from 6.0 to 10.0MPa and 1000°C, respectively. The resilience for metal jacketed gasket is low which is mainly depended on the materials. But high quality flanges with good surface and preload capability are required. It is usually used for heat exchanger, pressure vessel and valve flange, and so on.